LFT - long fiber-reinforced thermoplastic material, is compared with ordinary fiber-reinforced thermoplastic materials. Usually, the fiber length in fiber-reinforced thermoplastic materials is less than 1 mm. In LFT, the fiber length is generally greater than 2 mm. The current processing technology has been able to keep the fiber length in LFT above 5-10 mm.

In the automotive industry, LFT is mainly used to make structural and semi-structural components, such as front-end modules, bumper beams, dashboard frames, battery brackets, spare tire compartments, seat frames, foot pedals, and overall floor panels. Long fiber reinforced polypropylene is used in car hoods, dashboard frames, battery brackets, seat frames, car front-end modules, bumpers, luggage racks, spare tires, fenders, fan blades, engine chassis, and roofs. Lining rack etc.

| ||||||||||||||

| ||||||||||||||

| ||||||||||||||

| ||||||||||||||

| ||||||||||||||

| ||||||||||||||

| ||||||||||||||

| ||||||||||||||

| ||||||||||||||

| ||||||||||||||

| ||||||||||||||

| ||||||||||||||

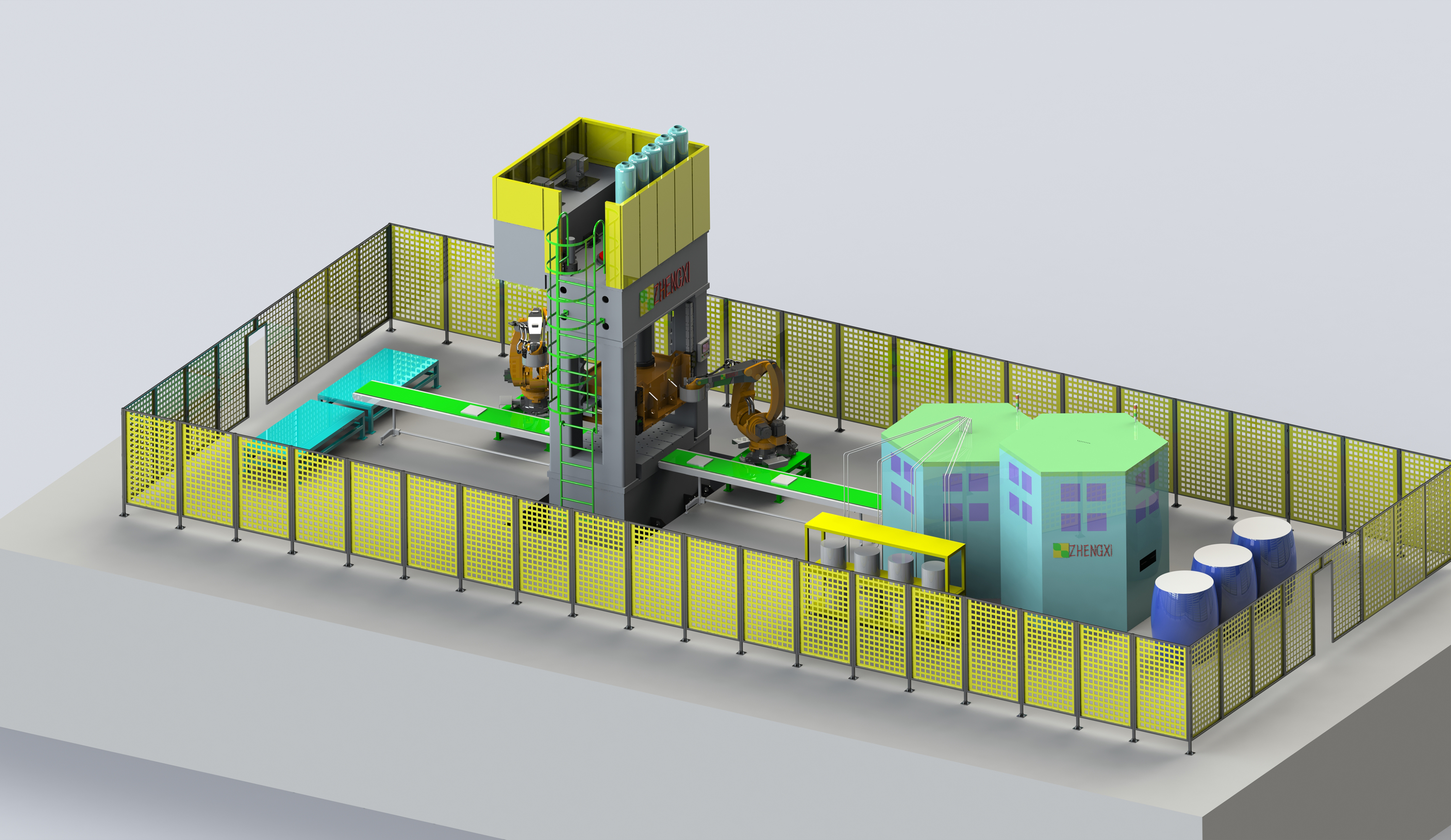

The pre-tightened frame has a detachable pre-tightened structure, making the whole machine highly rigid and easy to install.

The hydraulic system is equipped with a maintenance platform, which is environmentally friendly, low noise, and easy to maintain.

Servo high-speed precision control system, fast response speed, and high energy saving rate.